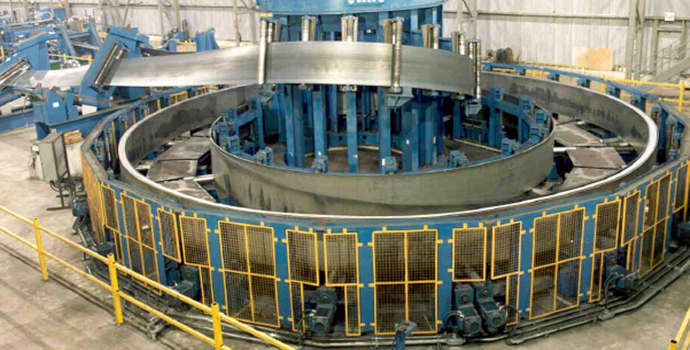

GEI-630 ERW steel tube mill

GEI-630 ERW steel tube mill is used to produce steel pipes with diamter of Φ219.1~ 630mm by steel strips width of 680-2000mm and thickness of 5.0-16.0mm, the finished pipe can meet the API-5L and ASME standard according to different usage and requirement.

Technical features of GEI-630 pipe mill machine

The rough forming part of this unit adopts the improved F.F.X forming system, which can adapts various specification of steel pipes of 85/8"~ 24". it shall be adjusted manually and electronically according to the scale and other tools when the rough forming part changing the specifications and thickness of each specification. The finishing forming part adopts 3 finishing forming stands. The sizing part adopts the arrangement of 4 (4 roller) stands and 2 straightening stand. The finishing forming stand and sizing stand adopts the method of changing roller outside of the line to save the roller change time.

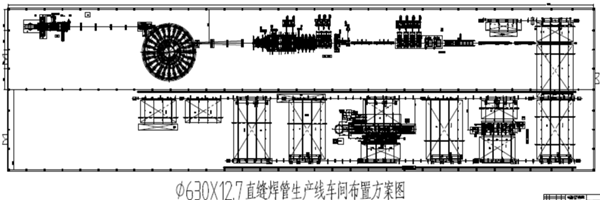

GEI-630 ERW steel pipe mill work process:

Preparing coil → uploading → uncoiling → leveling → shear and butt welder→ accumulator → leveling and centering → forming → HF welder → outer burr clean → inner burr clean → welded seam surface rolling → welded seam cooling → shaping and sizing → cut to length → output → end facing and chamfering → hydraulic tester → welded seam flaw detection → inspection → collection

GEI-630 ERW tube mill line configuration: it is composed of

| N/N | items | ||

| 1 | Loading car | 17 | Hydraulic system for main machine area |

| 2 | Uncoiler | 18 | End facing and chamfering machine |

| 3 | Coil opener | 19 | Hydraulic tester |

| 4 | Pinch and leveler | 20 | Roller table in finishing area |

| 5 | Shear and butt-welder | 21 | Receiving and pull-out pipe device in finishing area |

| 6 | Accumulator | 22 | Pipe stopper in finishing area |

| 7 | Centering device | 23 | Platform in finishing area |

| 8 | Five roller leveling machine | 24 | Anchor bolt for finishing area |

| 9 | Centering delivery device | 25 | Hydraulic system in finishing area |

| 10 | Forming machine | 26 | Electric control system in finishing area |

| 11 | Welding device | 27 | 1000KW HF welder |

| 12 | Sizing machine | 28 | Inner deburring device |

| 13 | Water cooling device | 29 | Milling saw |

| 14 | Roller table after cutting | 30 | Band saw |

| 15 | Anchor bolt for main machine area | 31 | Ultrasonic flaw detector |

| 16 | Electric control system for main machine area |

Next: Nepal customers visiting factory for GEI-76 ERW steel pipe mill project