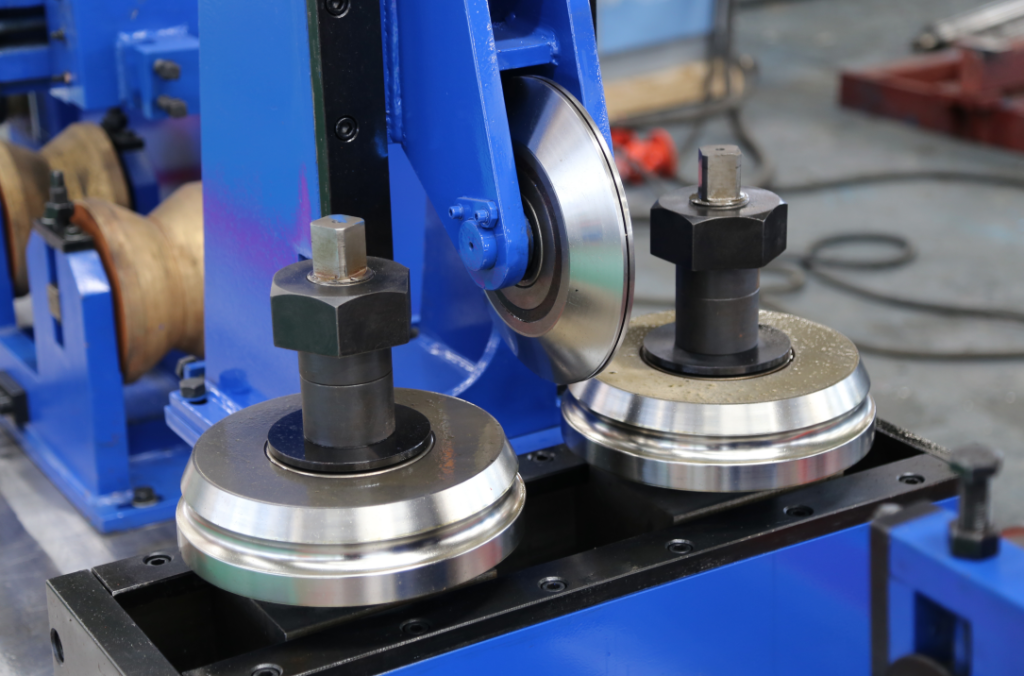

Some characteristics of roller for small diameter pipe welding machine abroad

During the 1980s and 1990s, with the renovation of domestic welded pipe plants and the construction of joint venture welded pipe plants, a large number of welded pipe sets manufactured abroad entered China. They came from developed countries such as the United States, Japan, Germany and other Western countries. These welded pipe sets mainly produce small-diameter thin-walled furniture pipes and special-shaped pipes. At the same time, they also introduced many rollers. The manufacturer reflects that the roll performance of the main belt is better than that of the domestic processing roll. What is the reason? During the years, they have had the opportunity to visit some joint venture welded pipe factories. They have seen many imported welded pipe production lines from abroad, contacted factories and technicians, and made some technical suggestions. Questions were exchanged. The general impression is that foreign colleagues attach great importance to the forming method of welded pipe, make the force distribution of rolls in the forming process more reasonable as far as possible, and also attach great importance to the study of roll pass design, configuration, material selection and processing methods. There are many unique opinions about rolls. Undoubtedly, it plays an important role in ensuring the quality of rolls. Some rolls used in small diameter welding pipe mills imported from abroad have the characteristics of material selection, pass design of processing methods, pass configuration and roll shape structure, which can be used for reference by domestic and roll mills in order to improve the quality of welded pipe rolls in China.

characteristics-of-roller-for-pipe-welding